Quality Metrics

Our Certifications

Internationally recognized standards that validate our commitment to quality

Quality Control Process

Our comprehensive approach to ensuring product excellence

Quality Standards and Certifications

Certifications

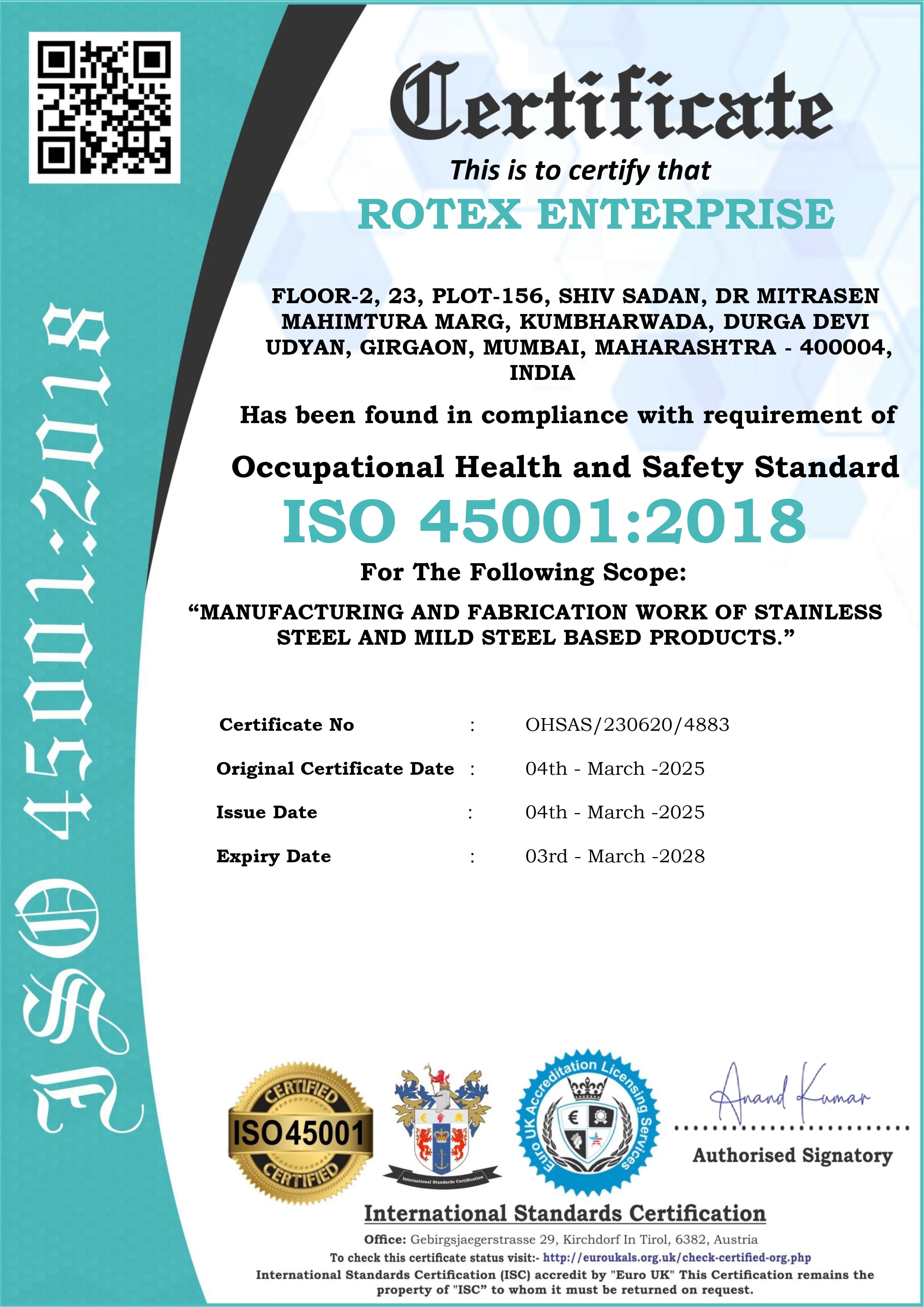

What certifications does Rotex Enterprise hold?

Rotex holds ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), ISO 45001:2018 (Occupational Health and Safety), and Udyam Registration certifications.

How does ISO 9001:2015 certification benefit customers?

ISO 9001:2015 certification ensures consistent quality, structured processes, and continuous improvement in all our manufacturing and service delivery.

What is the significance of ISO 14001 certification?

ISO 14001 certification demonstrates our commitment to environmental responsibility and sustainable manufacturing practices.

Quality Control Processes

How does Rotex ensure product quality?

We implement rigorous quality control measures at every stage of manufacturing, from material selection to final inspection, ensuring consistent product excellence.

What quality testing methods does Rotex use?

Rotex employs advanced testing methods including dimensional accuracy checks, material composition analysis, and durability testing for all products.

How does Rotex maintain quality in custom fabrication?

We follow strict quality protocols, use precision machinery, and conduct thorough inspections to ensure custom fabrication meets exact specifications.

Material Standards

What material quality standards does Rotex follow?

Rotex adheres to international material quality standards, using only certified raw materials that meet industry specifications.

How does Rotex ensure stainless steel quality?

We source high-grade stainless steel and perform rigorous testing to ensure material composition, finish quality, and corrosion resistance.

Our Quality Commitment

Rotex Enterprise maintains the highest standards of quality through comprehensive quality management systems, skilled workforce, and state-of-the-art manufacturing facilities.

Our commitment to quality extends beyond certifications to include continuous improvement, employee training, and customer satisfaction.

Manufacturing Excellence

What manufacturing standards does Rotex follow?

Rotex follows international manufacturing standards including ISO guidelines, industry-specific regulations, and custom quality parameters for specialized products.

How does Rotex maintain precision in manufacturing?

We use advanced CNC machinery, laser cutting technology, and precision measurement tools, combined with skilled craftsmanship to ensure exact specifications.

What is Rotex's quality inspection process?

Our quality inspection process includes multi-stage checks, dimensional verification, material testing, finish quality assessment, and final product validation.

Industry-Specific Quality Standards

How does Rotex ensure pharmaceutical grade quality?

We maintain cleanroom conditions for pharmaceutical furniture manufacturing, use FDA-compliant materials, and follow GMP guidelines for pharmaceutical industry products.

What quality measures are taken for retail products?

Our retail products undergo stress testing, finish durability checks, and aesthetic quality control to ensure long-lasting performance in high-traffic environments.

How does Rotex maintain infrastructure product quality?

Infrastructure products undergo rigorous load testing, weather resistance checks, and compliance verification with safety standards.

Quality Assurance and Customer Satisfaction

What is Rotex's quality guarantee?

We offer comprehensive quality guarantees including material quality assurance, workmanship warranty, and after-sales support for all our products.

How does Rotex handle quality concerns?

We have a dedicated quality control team that promptly addresses any quality concerns, provides immediate resolution, and implements preventive measures.

What quality documentation does Rotex provide?

We provide detailed quality certificates, material test reports, dimensional reports, and product compliance documentation with every order.

Quality Through Technology

How does technology improve Rotex's quality control?

We utilize advanced quality control software, digital measurement tools, and automated testing equipment to ensure consistent quality standards.

What quality monitoring systems does Rotex use?

We employ real-time quality monitoring systems, statistical process control, and automated inspection systems throughout our manufacturing process.