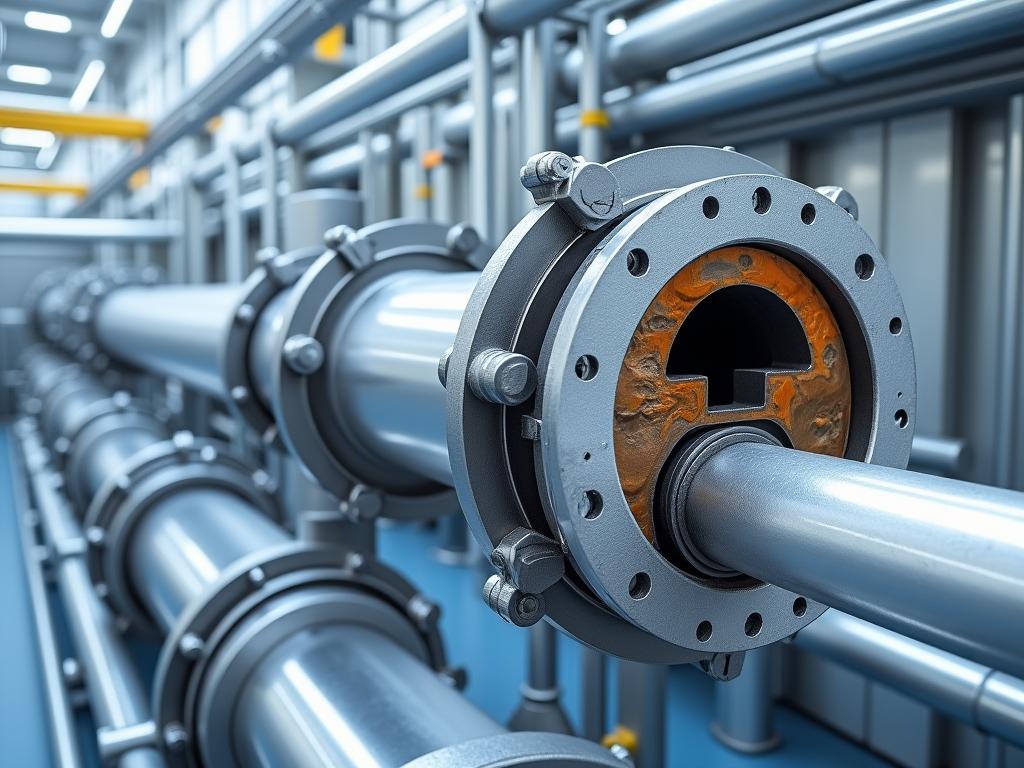

Rotex Enterprise has long stood as a benchmark of quality and innovation in industrial manufacturing, and their Industrial Piping Solutions are a prime example of excellence. In this comprehensive overview, we explore the intricate details and robust engineering behind products such as Mechanical Polish Tee, Electro Polish Tee, Mechanical Polish Elbow, Electro Polish Elbow, Mechanical Polish Pipe, and Electro Polish Pipe. Each product is meticulously designed to deliver optimal performance under demanding industrial conditions. The company’s dedication to quality is evident in every step of the production process—from the initial design phases to the final quality assurance tests. In addition, the enterprise's R&D team collaborates closely with industry experts to incorporate cutting-edge technology and innovative materials into their product design, thereby enhancing mechanical properties and aesthetic appeal. Whether deployed in high-pressure systems or specialized industrial setups, these piping solutions are engineered to offer long-lasting performance and resistance to wear. This customer-centric approach, combined with technical excellence, ensures that each piping solution delivers exceptional value and reliability, making it an indispensable asset for modern industrial infrastructures.

At the heart of these Industrial Piping Solutions lies a sophisticated manufacturing process that seamlessly blends traditional craftsmanship with state-of-the-art technology. Detailed design specifications are first developed using advanced CAD software, which maps out every dimension and curve with utmost precision. Following the design phase, precision laser cutting transforms raw materials into perfectly shaped components, ensuring even the most intricate designs are executed flawlessly. This is complemented by high-accuracy bending work that aligns each component with strict industry requirements. Throughout the process, automated quality control systems and rigorous testing protocols are employed to guarantee that every product meets and exceeds the highest standards of precision and durability. By continuously refining these techniques and embracing the latest technological advancements, Rotex Enterprise reinforces its commitment to excellence and innovation in every component it produces.

Performance and durability remain the hallmarks of Rotex Enterprise's piping solutions. These products are engineered to withstand extreme pressures, corrosive environments, and continuous operation without degradation. Extensive testing—ranging from stress analysis to thermal performance evaluations—ensures that each product can endure the harshest industrial conditions. Moreover, the exceptional surface finishes achieved through both mechanical and electro polishing reduce friction and optimize flow dynamics. These enhancements lead to improved system efficiency and lower maintenance costs for end users. As a result, customers benefit from increased uptime and a marked reduction in operational disruptions, making these piping solutions a reliable choice for critical industrial applications.

Innovation and sustainability are two core principles driving the evolution of these products. Rotex Enterprise continually explores new materials and modernizes its manufacturing techniques to meet the ever-changing demands of the industrial sector. Eco-friendly practices, such as recycling metal offcuts and optimizing energy consumption, are integrated throughout the production process. This sustainable approach not only reduces environmental impact but also translates into significant cost savings and improved product quality. In addition, the incorporation of smart sensors and real-time monitoring systems facilitates data-driven decision making, ensuring continuous improvement. This forward-thinking mindset positions Rotex Enterprise as a leader in next-generation industrial solutions, with piping components that are both technologically advanced and environmentally responsible.

Looking ahead, Rotex Enterprise is set to expand its leadership in industrial piping by investing in next-generation technologies and strategic partnerships. Future initiatives include further automation, deeper integration of digital manufacturing tools, and even more rigorous quality standards. As global industries continue to prioritize innovation, reliability, and sustainability, the company’s piping solutions will remain pivotal in powering modern infrastructures. In conclusion, these Industrial Piping Solutions epitomize a perfect blend of advanced engineering, meticulous craftsmanship, and environmental stewardship, ensuring that every product not only meets the current market demands but is also primed for future challenges.